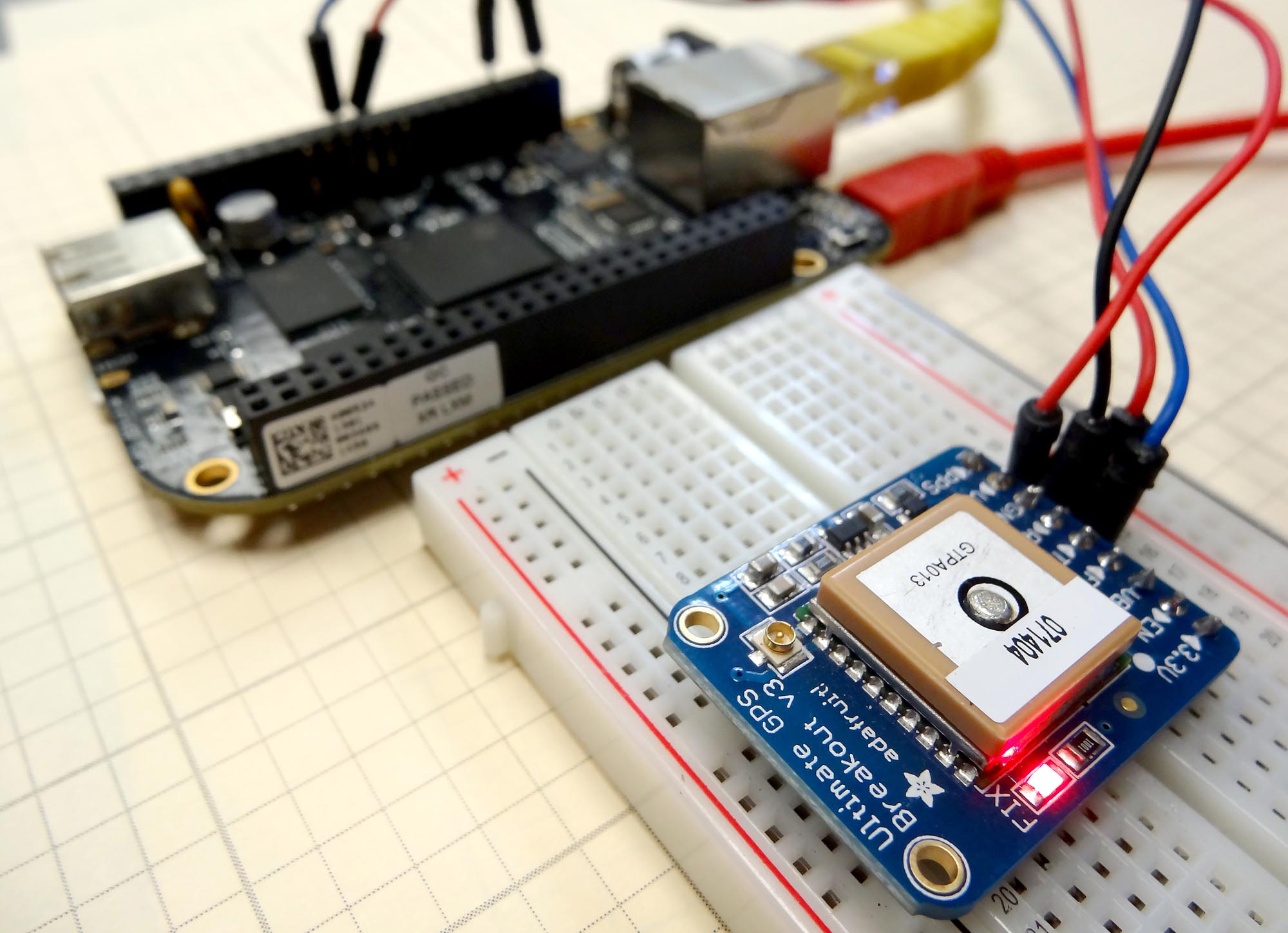

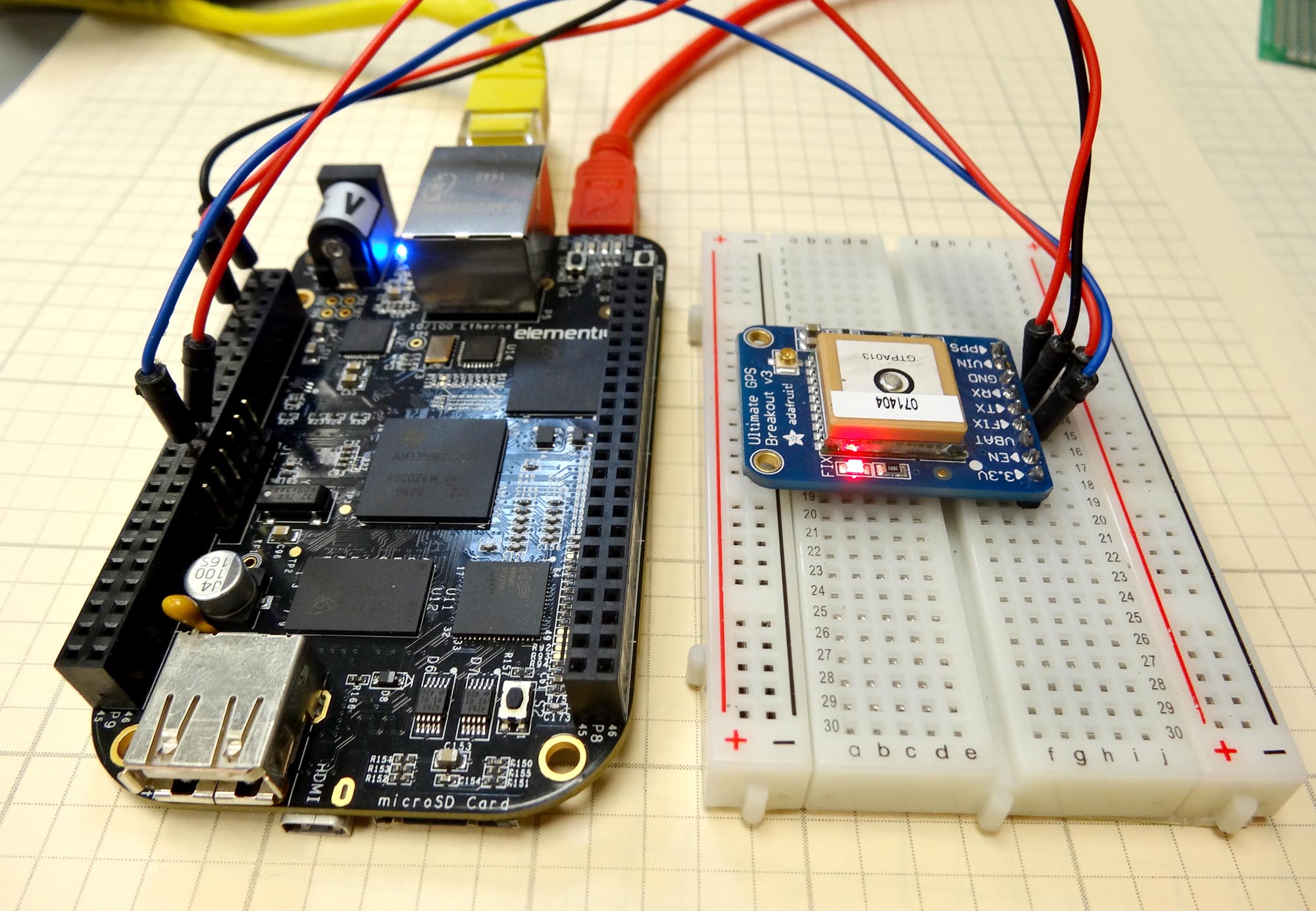

import serial

import Adafruit_BBIO.UART as UART

from time import sleep

UART.setup("UART1")

ser=serial.Serial('/dev/ttyO1',9600)

class GPS:

def __init__(self):

#This sets up variables for useful commands.

#This set is used to set the rate the GPS reports

UPDATE_10_sec= "$PMTK220,10000*2F\r\n" #Update Every 10 Seconds

UPDATE_5_sec= "$PMTK220,5000*1B\r\n" #Update Every 5 Seconds

UPDATE_1_sec= "$PMTK220,1000*1F\r\n" #Update Every One Second

UPDATE_200_msec= "$PMTK220,200*2C\r\n" #Update Every 200 Milliseconds

#This set is used to set the rate the GPS takes measurements

MEAS_10_sec = "$PMTK300,10000,0,0,0,0*2C\r\n" #Measure every 10 seconds

MEAS_5_sec = "$PMTK300,5000,0,0,0,0*18\r\n" #Measure every 5 seconds

MEAS_1_sec = "$PMTK300,1000,0,0,0,0*1C\r\n" #Measure once a second

MEAS_200_msec= "$PMTK300,200,0,0,0,0*2F\r\n" #Meaure 5 times a second

#Set the Baud Rate of GPS

BAUD_57600 = "$PMTK251,57600*2C\r\n" #Set Baud Rate at 57600

BAUD_9600 ="$PMTK251,9600*17\r\n" #Set 9600 Baud Rate

#Commands for which NMEA Sentences are sent

ser.write(BAUD_57600)

sleep(1)

ser.baudrate=57600

GPRMC_ONLY= "$PMTK314,0,1,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0*29\r\n" #Send only the GPRMC Sentence

GPRMC_GPGGA="$PMTK314,0,1,0,1,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0*28\r\n"#Send GPRMC AND GPGGA Sentences

SEND_ALL ="$PMTK314,1,1,1,1,1,1,0,0,0,0,0,0,0,0,0,0,0,0,0*28\r\n" #Send All Sentences

SEND_NOTHING="$PMTK314,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0*28\r\n" #Send Nothing

ser.write(UPDATE_200_msec)

sleep(1)

ser.write(MEAS_200_msec)

sleep(1)

ser.write(GPRMC_GPGGA)

sleep(1)

ser.flushInput()

ser.flushInput()

print "GPS Initialized"

def read(self):

ser.flushInput()

ser.flushInput()

while ser.inWaiting()==0:

pass

self.NMEA1=ser.readline()

while ser.inWaiting()==0:

pass

self.NMEA2=ser.readline()

NMEA1_array=self.NMEA1.split(',')

NMEA2_array=self.NMEA2.split(',')

if NMEA1_array[0]=='$GPRMC':

self.timeUTC=NMEA1_array[1][:-8]+':'+NMEA1_array[1][-8:-6]+':'+NMEA1_array[1][-6:-4]

self.latDeg=NMEA1_array[3][:-7]

self.latMin=NMEA1_array[3][-7:]

self.latHem=NMEA1_array[4]

self.lonDeg=NMEA1_array[5][:-7]

self.lonMin=NMEA1_array[5][-7:]

self.lonHem=NMEA1_array[6]

self.knots=NMEA1_array[7]

if NMEA1_array[0]=='$GPGGA':

self.fix=NMEA1_array[6]

self.altitude=NMEA1_array[9]

self.sats=NMEA1_array[7]

if NMEA2_array[0]=='$GPRMC':

self.timeUTC=NMEA2_array[1][:-8]+':'+NMEA1_array[1][-8:-6]+':'+NMEA1_array[1][-6:-4]

self.latDeg=NMEA2_array[3][:-7]

self.latMin=NMEA2_array[3][-7:]

self.latHem=NMEA2_array[4]

self.lonDeg=NMEA2_array[5][:-7]

self.lonMin=NMEA2_array[5][-7:]

self.lonHem=NMEA2_array[6]

self.knots=NMEA2_array[7]

if NMEA2_array[0]=='$GPGGA':

self.fix=NMEA2_array[6]

self.altitude=NMEA2_array[9]

self.sats=NMEA2_array[7]

myGPS=GPS()

while(1):

myGPS.read()

print myGPS.NMEA1

print myGPS.NMEA2

if myGPS.fix!=0:

print 'Universal Time: ',myGPS.timeUTC

print 'You are Tracking: ',myGPS.sats,' satellites'

print 'My Latitude: ',myGPS.latDeg, 'Degrees ', myGPS.latMin,' minutes ', myGPS.latHem

print 'My Longitude: ',myGPS.lonDeg, 'Degrees ', myGPS.lonMin,' minutes ', myGPS.lonHem

print 'My Speed: ', myGPS.knots

print 'My Altitude: ',myGPS.altitude